- January 13, 2025

Geotechnical Investigation – Onshore and Offshore

Onshore geotechnical investigation involves assessing soil and rock properties at land-based project sites to ensure safe and efficient foundation design. It includes fieldwork like borehole drilling, in-situ testing, and lab analysis to determine subsurface conditions. This process helps minimize construction risks and supports informed engineering decisions.

Offshore geotechnical engineering is a sub-field of geotechnical engineering. It is concerned with foundation design, construction, maintenance and decommissioning for human-made structures in the sea. Oil platforms, artificial islands and submarine pipelines are examples of such structures. The seabed has to be able to withstand the weight of these structures and the applied loads. Geohazards must also be taken into account. The need for offshore developments stems from a gradual depletion of hydrocarbon reserves onshore or near the coastlines, as new fields are being developed at greater distances offshore and in deeper water with a corresponding adaptation of the offshore site investigations.

Geotechnical Field Tests

Standard Penetration Test

Soil exploration, collection and handling of disturbed and undisturbed samples as per IS Standards to any depth irrespective of character of the invisible material by employment of sophisticate Equipment (including Rock drilling). Tests on samples such as Analysis of Allowable Bearing Pressure of Soil, Recommendation on foundation etc. and other specific specialized applications.

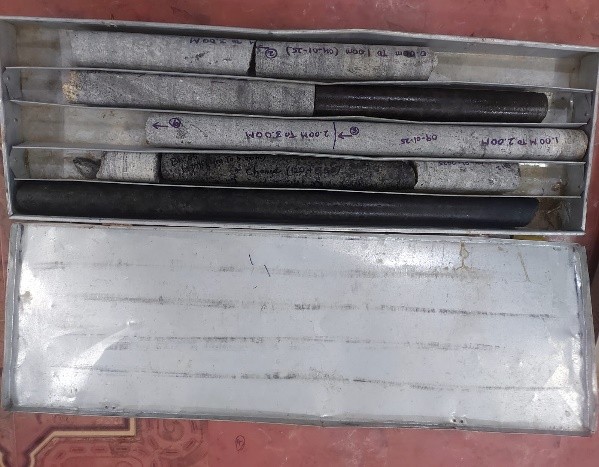

Drilling, sampling and field testing in soil and rock

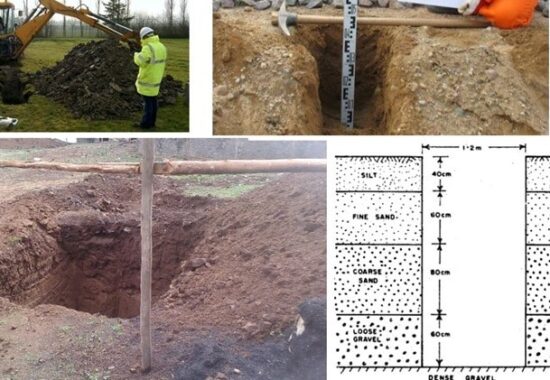

Trial Pits

A trial pit (or test pit) is an excavation of ground in order to study or sample the composition and structure of the subsurface, usually dug during a site investigation, a soil survey or a geological survey. Trial pits are dug before the construction. They are dug to determine the geology and the water table of that site.

Trial pits are usually between 1 and 4 metres deep, and are dug either by hand or using a mechanical digger. Building and construction regulations clearly state that any trial pits that concede deeper than 1.2 metres should be secured against structural collapse, if they are to be entered by people.

The Plate Bearing Test (or Plate Loading Test) is an insitu load bearing test of soil used for determining the ultimate bearing capacity of the ground and the likely settlement under a given load…. The Plate Bearing Test is normally carried out at foundation level, either on the surface or in a shallow pit.

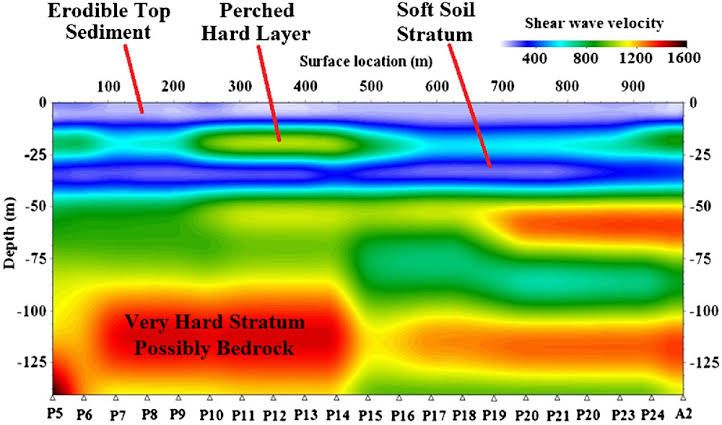

MASW Testing (Multichannel Analysis of Surface Waves)

At Josmar, we offer MASW (Multichannel Analysis of Surface Waves) testing as part of our geophysical services to assess subsurface soil stiffness profiles with high reliability and minimal disruption.

MASW is a non-invasive seismic method used to evaluate the shear-wave velocity (Vs) of subsurface materials. Shear-wave velocity is a critical parameter in geotechnical engineering, commonly used in:

- Soil classification

- Earthquake site response analysis

- Liquefaction potential evaluation

- Foundation design

MASW involves generating surface waves using a controlled seismic source (such as a sledgehammer) and recording the wave propagation with an array of geophones. The data collected is processed to produce a profile of the subsurface layers, typically to depths of 10–30 meters or more depending on the site.

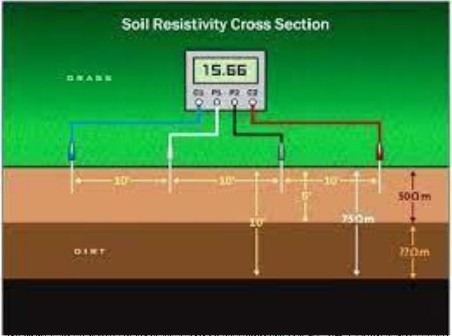

Electrical Resistivity Test

Earth resistivity is the measurement of the specific resistance of a given material…. The soil resistivity test spaces four (4) probes out at equal distances to approximate the depth of the soil to be tested. Readings are taken at different spacings as technical per standard.

Field & Lab density Test by core cutter method

FDT is soil compaction test is a Quality Control test carried out at site for knowing the increased density or compaction achieved at site on the soil layer. FDT is a part of in-situ soil testing which is one of the subjects of geotechnical engineering

Block vibration test

Cross-hole and Down-hole seismic test

Pressure meter test

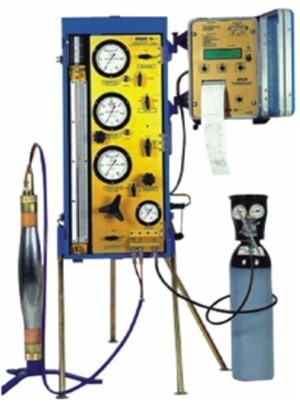

Static cone penetration test

The static cone penetration test is also known as the Dutch cone test. This test is standardized by, “IS: 4968 (Part III)- 1976– Method for subsurface sounding for soils- Part III static cone penetration test”.

The static cone penetration test is a type of cone penetration test in which cone is used to penetrate the ground surface. In SCPT, we do not apply any hammer blow as in DCPT. We push the hammer into the soil at a particular rate of 1 cm/sec. In the case of SCPT, we will be measuring continuous data so we will get continuous measurements of the resistance to penetration of the cone and a surface sleeve.

The static cone penetration test is done with the help of static cone penetrometer. Static cone penetrometer consists of a steel cone, a friction jacket, sounding rod, mantle tube, a driving mechanism and measuring equipment.

Field California Bearing Ratio (CBR)

The Field California Bearing Ratio (CBR) test is a crucial test in the evaluation of the strength and bearing capacity of soil for road and pavement design. It helps determine the thickness of pavement layers and assesses the subgrade’s ability to support traffic loads, without deformation.

Other Field Services

• Thermal resistivity test.

• Dynamic cone penetration test.

• Field & Lab vane shear test.

• Field permeability test.